Introduction

MODWAL now supplies Fully Automatic Movable Partition System where the entire operation of the partition wall right from the movement of the panels from the stacking area to the main track, positioning and locking of panels takes place automatically by push of the button.

MODWAL is the first manufacturer of total Automatic Partition System in India. MODWAL uses all locally manufactured items and microprocessor based advanced controller for the operation of the partition.

Fully Automatic Movable Partitions are much demanded in high end office fit outs and banquets where customers seeks operating convenience, luxury and total automatic operation. Thus reducing the need for manually operating the panel.

Product Features / Material Description

Intelligent control of industrial automation and advanced mechanical design and manufacturing

- Combined the semi-automatic system with the fully automatic drive system.

- High Strength 6063-T6 Aluminium alloy Guide Track.

- Customized motors of German technology.

- Fully automatic control system, one-touch operation.

- When an accidental power down, a manual operation function to ensure normal passage of personnel.

- Industrial intelligent control to automatically control the operation of the entire partition wall.

- Programmable control for automatic control of each panel. The motors of each panel are equipped with opticalencoders for position control of each panel.

- The main power motor controls the extension and storing of the panels

- Motor-controlled drive system, top and bottom retractable seal and telescopic closure panel.

- Travel speed : 100~250mm/s

Features

- Electrical movable wall facilitate quick setup time and provide efficient and convenientseparation.

- Electric operation provides fully automatic setup without the need for manually moving thepartitions into place.

- The power supply of system is 24V safe voltage , so as to avoid the risk of electric shockduring the use of the product.

- Electric partitions are suitable for lots of places such as hotels, boardrooms, school, gyms,classrooms, training rooms etc.

- Full intelligent design, Totally automatic electric operation, convenient and quick for separation.

Technical Specifications

Maximum Height – HW | 7000mm (Single – Point) |

Maximum Height –HW | 15000mm (Double – Point) |

Track load bearing capacity | 750kg/m (Single – Point) |

Track load bearing capacity | 1250kg/m (Double – Point) |

Panel Height Min(mm) | 2000 |

Power supply voltage AC | 150V – 250V |

Motor Frequency | 50-60HZ |

Main Drive motor power | 100W |

Closing Force | F200N < F < 400N |

Manual Thrust (when power down) | < 350N |

Motor Noise | ≤ 50dB |

Operating Ambient Temperature | -20°C ~ +60°C |

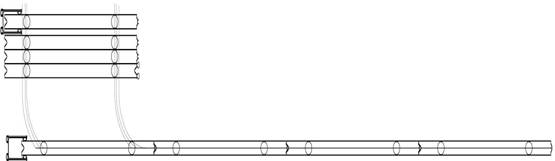

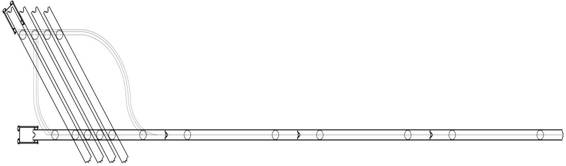

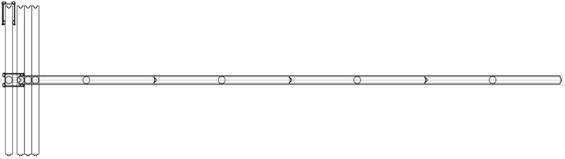

Parking Patterns

A Variety of parking configurations can be made using electrically powered track and curved junctions. Some of the Stacking layouts of fully automatic movable wall are outlined below.

Parallel Stack

Panels are parked parallel to the main track.

Pros: Takes up less space for parking.

Cons: Panels are parked in the middle of the hall and need extra structural support work.

Side Stack

Panels are parked sideways or off-set to the main track at 75° inclination for smooth travel of panels from main track to the stacking area.

Pros: Less space required for stacking.

Cons: Need Extra structural support work.

Centre Stack

Basic system of stacking along the centre line of main track.

Pros: Simple stacking and less area required.

Cons: Cannot be used for complex layouts.

The Materials of Fully Automatic Partition Wall

Angle Steel | 8# Angle Steel |

Square Tube | 12# Channel Steel |

Steel Joint Plate | 260*160*8 Steel Plate |

Isolated Conductor Rail (ICR) | Copper |

Double-Safe Carbon Brush | Copper + Carbon |

Guide Track | 6063-T5 Anodized Aluminium |

Sound Insulation Rock Wool | PAR Sound-absorbing Ultra-high-density Fibreglass |

Rubber Seal Strip | Imported PVC + Butyronitrile |

Auto-balance hanger | 6063-T5 Anodized Aluminium |

Nut Wide-tooth Timing Belt | PAR Sound-absorbing Ultra-high-density Fibreglass |

AUTOMATIC MOVABLE WALLS: STORED POSITION

PANEL DETAILS & SPECIFICATIONS

MODELS | TYPE 80 SOLID | TYPE 100 SOLID | TYPE 100 GLASS |

|---|---|---|---|

OPERATION | ELECTRICALLY OPERATED | ELECTRICALLY OPERATED | ELECTRICALLY OPERATED |

THICKNESS | 80mm | 100mm | 100mm |

MAX HEIGHT | 5000mm | 7000mm | 3600mm |

CONFIGURATION | CENTRE/TWO POINT SUSPENSION | CENTRE/TWO POINT SUSPENSION | CENTRE/TWO POINT SUSPENSION |

TOP/BOTTOM SEAL TRAVEL DISTANCE | 30mm | 30mm | 30mm |

PANEL WEIGHT | 28-38Kg/m² | 40-45Kg/m² | 38-40Kg/m² |

CLOSURE | TELESCOPIC PANEL ONLY | TELESCOPIC PANEL ONLY | TELESCOPIC PANEL ONLY |

TRACK | FULLY AUTOMATIC | FULLY AUTOMATIC | FULLY AUTOMATIC |

Track and Trolley

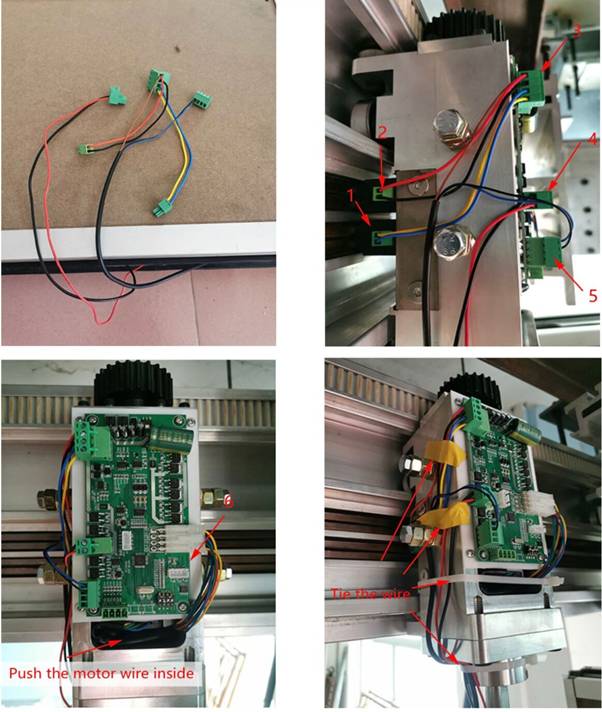

SCHEMATIC DIAGRAM OF AUTOMATIC TRACK WITH TROLLEY AND INBUILT PCB CONTROLLER

FULLY AUTOMATIC MOVABLE WALL: COMBINATION OF GLASS WALL AND SOLID PANELS